TOOLING & ADVANCED ENGINEERING

TOOLING & ADVANCED ENGINEERING

Tooling

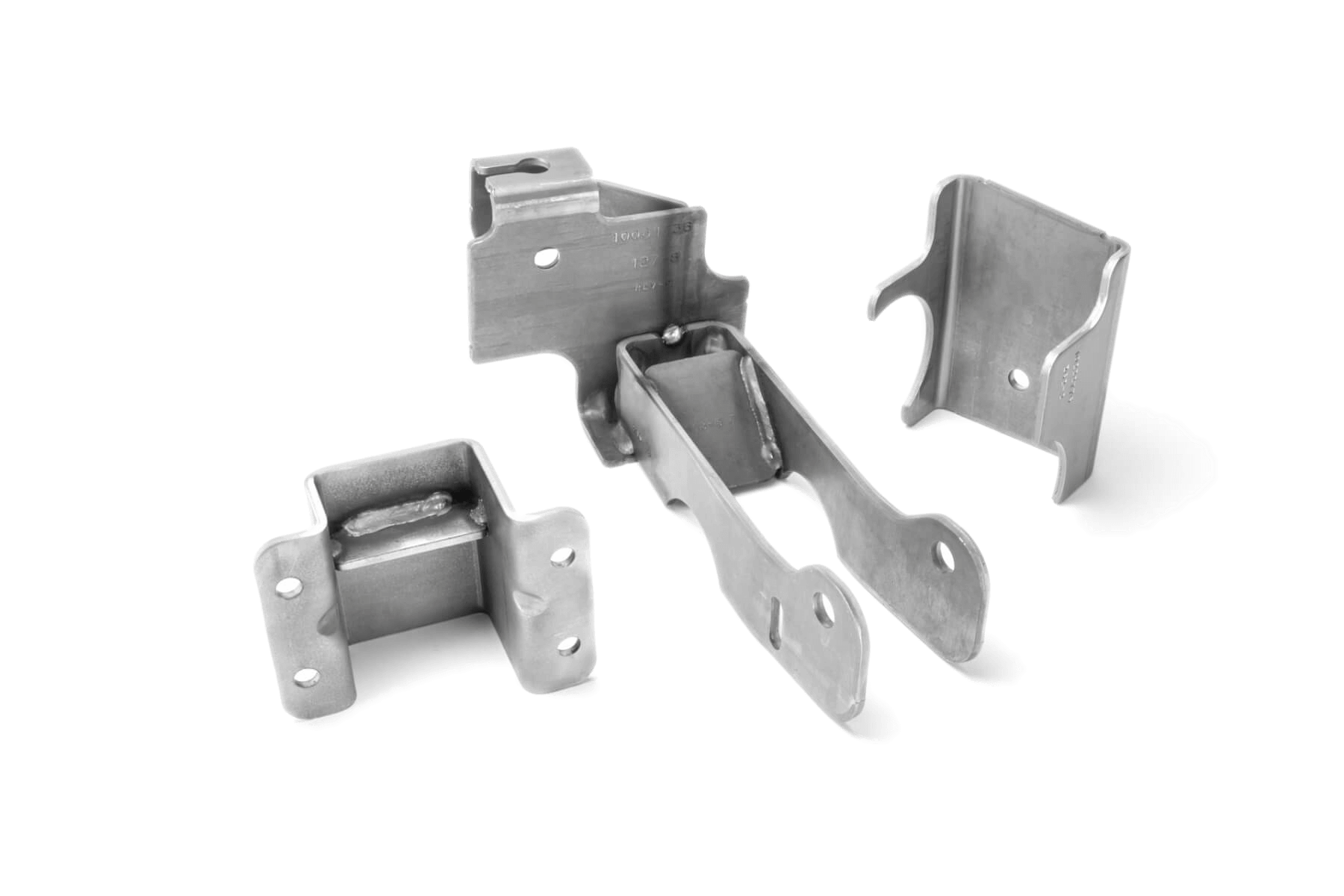

Wayne’s foundation is rooted as a tool and die shop dating to 1963. Since the company’s inception, Wayne has continually invested to meet customer needs and advancements in technology. Wayne utilizes 3-D modeling and the latest software packages available to support customer designs.

Wayne tool build capabilities include state-of-the-art EDM wire equipment and CNC machining to ensure the precision and accuracy of the tool build and the highest possible quality. Tooling is designed and built on site offering quick turnaround and the ability to make design changes with as little disruption to the construction timeline as possible.

TOOLING & ADVANCED ENGINEERING

Advanced Engineering

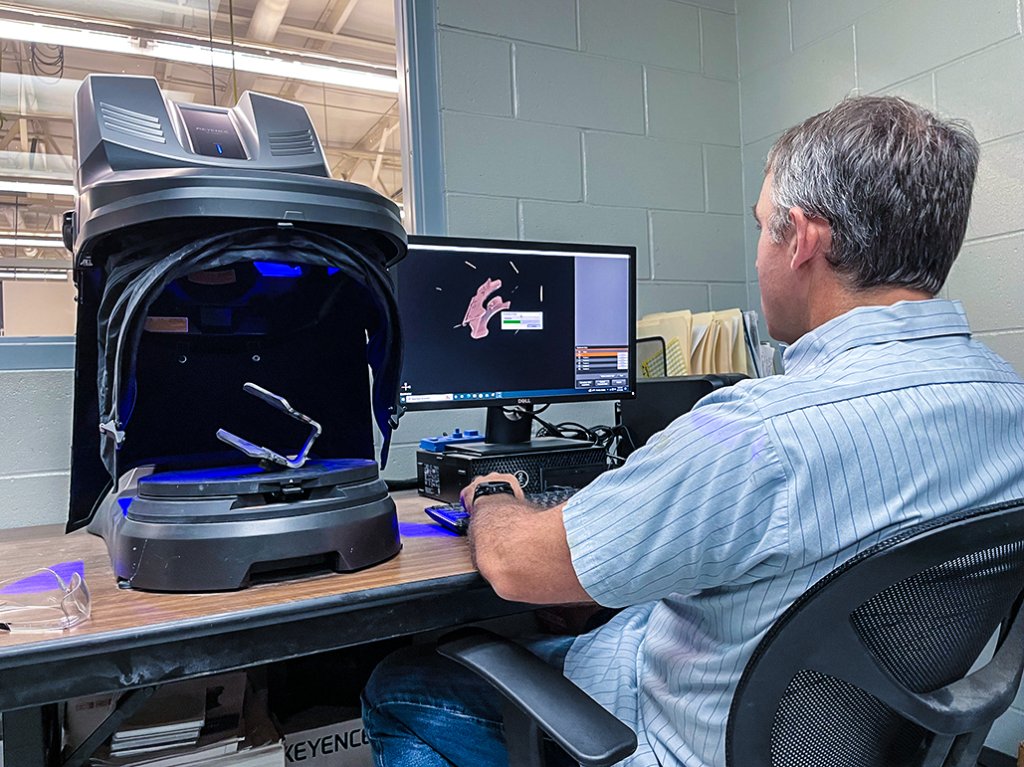

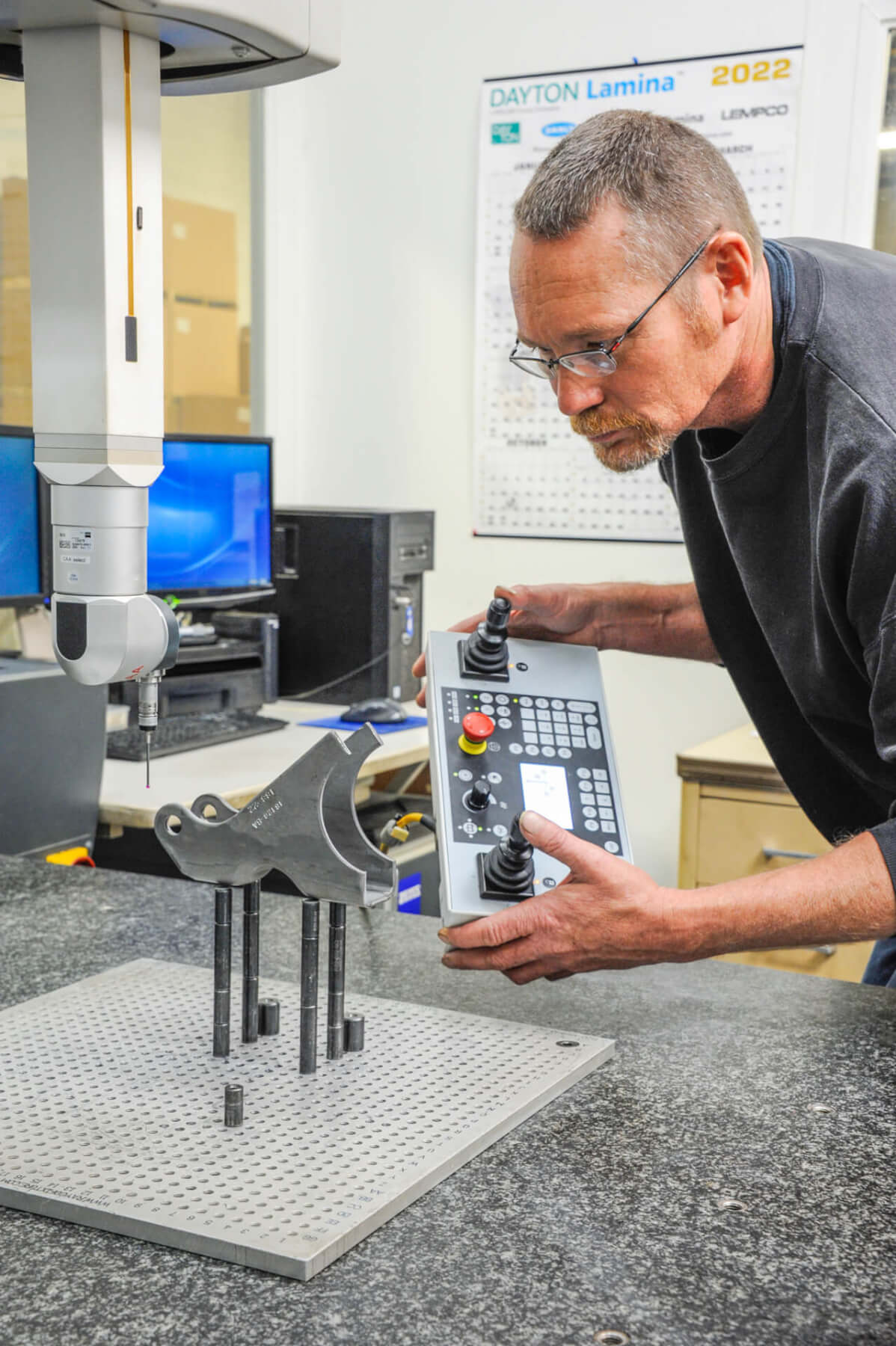

Wayne engineers work directly with customer engineering teams on product designs to maximize cost savings and manufacturability. Wayne utilizes the latest engineering software packages used by OEMs and Tier 1’s including 3-D scanning, 2-D optical comparator, and CMM.

STAMPING

Wayne is ideally suited in location and capabilities to support the expanded use of advanced alloys; Wayne’s production lines are well suited to the requirement of segregating various grades of material in scrap form.

WELDING

Wayne operates multiple manual and automated Mig and Resistance Welding systems.

Utilizing automation whenever possible, robotic welding is used to complete jobs more efficiently as well as maintaining a high level of reliability and weld quality. Special automation equipment is also used to assemble components to customer specifications. Wayne was an early adopter of robotic welding and has therefore amassed a significant amount of expertise.

MACHINING

Precision machining and automation are used to machine stamped components and welded assemblies. Computer Numerical Control (CNC) machining is utilized for components that require close tolerances. Customers increasingly require machining as components become more customized.

ASSEMBLY

In addition to core tool build and stamping capabilities, Wayne has in-house robotic welding, CNC machining and automated assembly equipment to support the needs of customers. This vertical integration allows customers a “one-stop-shop” for complex, multi process assemblies. Wayne has also demonstrated a willingness to invest in new and advanced technologies to support changing customer designs.

Prototype & Advanced Material Development

Prototype & Advanced Material Development

Prototype

Wayne has a long and established history of creating custom dies stretching back to the Company’s early roots in 1963. Wayne’s in-house tool and die shop provides the ability to quickly test and re-test tooling to achieve demanding specifications, giving Wayne and its customers an edge in product execution.

Prototype & Advanced Material Development

Advanced Material Development

QUALITY

Wayne Manufacturing’s dedication to quality starts with the design of the tooling and continues through the process development and manufacturing stage. Custom build gaging and electronic measuring devices are used to ensure part compliance and capability. The quality system has been designed to meet current automotive standards and customer specific requirements adhering to the standards of our IATF 16949 certification. Regular management meetings are held to address continuous improvement ideas and strategies. Employee meetings are conducted to discuss performance and opportunities for improvement.

Quality

Fully Staffed Quality Laboratory with the latest equipment & capabilities

- Zeiss CMM with Calypso Software

- Zwick Roell Tensile Testing Capabilities

- Keyence Optical Comparator

- Keyence 3-D Scanning Capability

- Microscopic weld analysis with Paxcan & Pax-it software

IATF 16949:2016 Certified

IATF 16949:2016 Certified

Wayne Manufacturing’s Quality Management System is proudly certified by NSF-ISR for IATF 16949:2016 standard. This scope includes conformance in metal stamping with robotic welding, machining and assembly capabilities.